Greg Sheridan

Marketing Manager

Posted on January, 17, 2024

Categories

Recent Posts

- Octavo Systems Unveils the OSD32MP2 Series: Revolutionizing System Design in the Electronics Industry April 9, 2024

- Securing the Future: The Integral Role of SiP Technology in Thwarting Physical Attack Vectors in Embedded Systems March 12, 2024

- Developing Secure Embedded Systems: Best Practices and Strategies March 12, 2024

- Heterogeneous Integration (HI) and System-in-Package (SiP) Technology: A Comprehensive Overview February 20, 2024

- Understanding The Differences Between System-on-Chip (SoC), Package-on-Package (PoP), System-on-Module (SoM), and System-in-Package (SiP) January 17, 2024

Understanding The Differences Between System-on-Chip (SoC), Package-on-Package (PoP), System-on-Module (SoM), and System-in-Package (SiP)

For electronic systems design, efficiency, innovation, and integration are key. Electronic design engineers constantly seek solutions that offer robust performance, are cost-effective, and streamline the design process. This is where understanding different semiconductor packaging technologies – System-in-Package (SiP), Package-on-Package (PoP), System-on-Chip (SoC), and System-on-Module (SoM) – becomes crucial.

System-on-Chip (SoC)

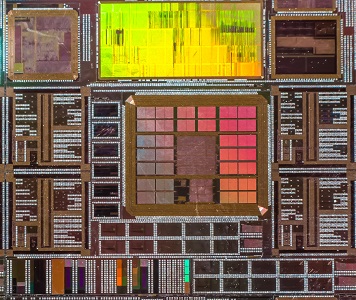

Definition and Usage: System-on-Chip (SoC) integrates almost all components of a computer or electronic system into a single silicon chip. It may include a CPU, GPU, memory, USB controller, power management circuits, and wireless transceivers.

Real-World Example: Home gaming consoles like the PlayStation and Xbox often utilize custom SoCs. These SoCs integrate graphics, computing cores, and memory controllers to handle specific gaming requirements.

Pros:

- Small and Highly Integrated: SoC’s compact design integrates numerous functions, making it ideal for space-constrained applications.

- Cost-Effective Per Device: On a per-device basis, SoCs are generally more cost-effective due to their high level of integration.

Cons:

- Lack of Flexibility: SoCs are designed for specific functions, offering little to no flexibility to handle functions they weren’t designed for.

- High Development Cost: Developing a new SoC is an expensive and resource-intensive process.

- Complexity in Using Discrete Versions: Incorporating discrete versions of SoCs can be complex and prone to errors.

- Limited Scope: SoCs usually represent only a small part of the overall system, requiring additional components for complete functionality.

Package-on-Package (PoP)

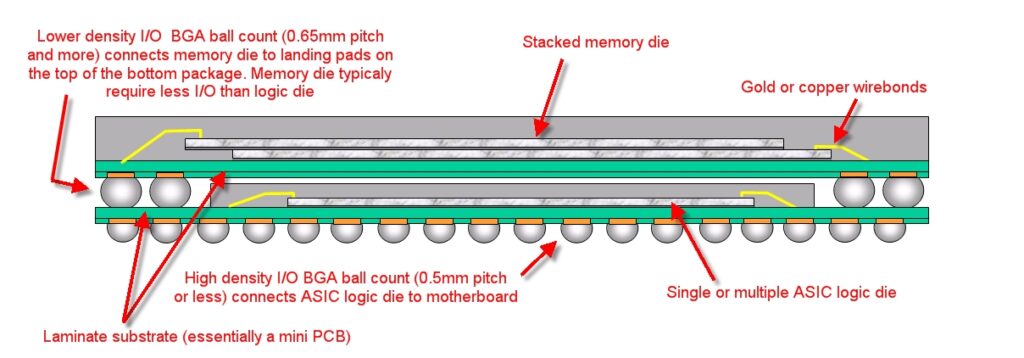

Definition and Usage: PoP technology stacks multiple semiconductor packages, typically memory on top of a processor, using a standard interface. This stacking allows for higher density without expanding the footprint, making it ideal for space-constrained applications.

Real-World Example: Smartphones did often use PoP to stack memory (like RAM) on top of the application processor. This configuration saves space and allows for quick communication between memory and processor.

Pros:

- Space Efficiency: PoP allows for significant space savings in the X/Y dimensions by stacking components in the Z direction.

Cons:

- Limited Device Integration: Typically limited to integrating processors and memory, offering less flexibility in component variety.

- Manufacturing Challenges: PoP can be difficult to manufacture with, often requiring precise alignment and handling.

- High-Volume Manufacturing: Best suited for high-volume manufacturing, which may not be feasible for smaller-scale projects.

- Partial System Solution: PoP addresses only a portion of the system’s requirements, necessitating additional components for a complete solution.

System-on-Module (SoM)

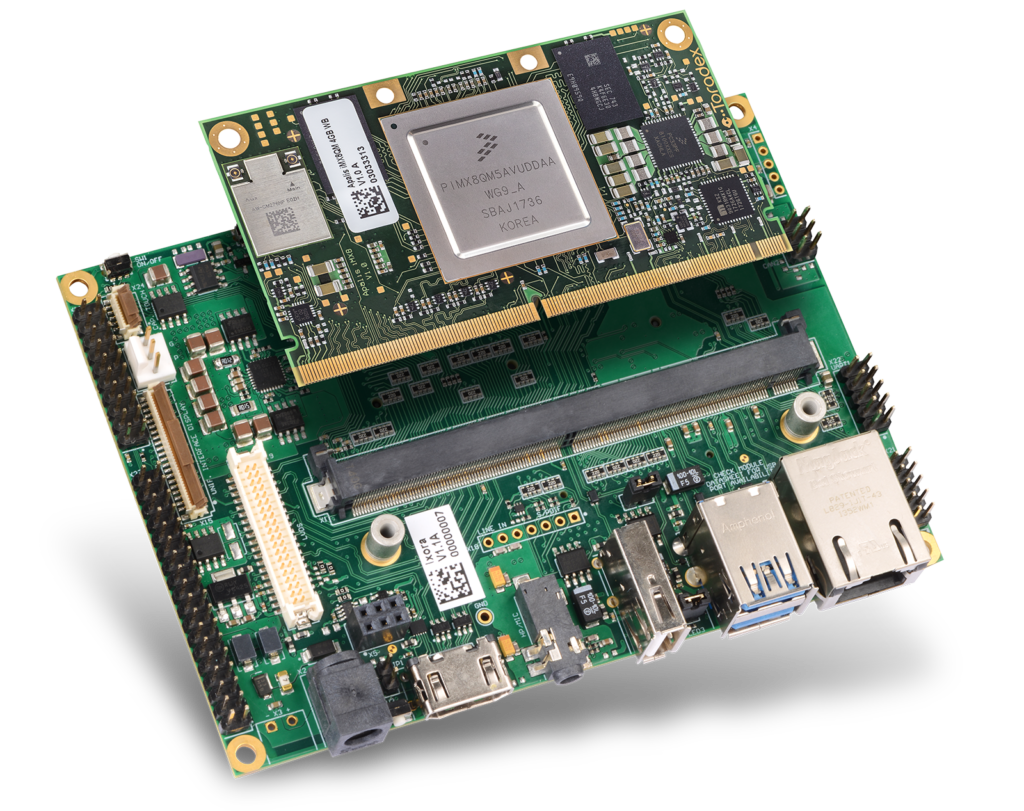

Definition and Usage: SoM is a board-level circuit that integrates a system function in a single module. It includes a microprocessor or microcontroller, memory, input/output (I/O) interfaces, and other necessary features. SoM is used in a parent (base) board where additional components are added.

System-on-Module (SoM) is a unique approach in electronic design that leverages printed circuit board (PCB) manufacturing technologies. This method involves integrating multiple-packaged System-on-Chips (SoCs) into a single module. By doing so, SoM combines the functional complexity and processing power of several SoCs, while maintaining the flexibility and customization options afforded by traditional PCBs. This integration strategy not only simplifies design and development processes but also accelerates time-to-market for complex electronic products. SoM is particularly advantageous in applications where design agility, modularity, and scalability are paramount.

Real-World Example: Industrial automation systems often use SoMs for their control units. These modules provide the necessary processing power and interfaces, while the base board is customized for specific industrial applications.

Pros:

- Rapid Development: SoM allows for quick development of a complete compute system, significantly reducing time-to-market.

- Flexibility: Offers a range of options in terms of processing power and functionalities, accommodating diverse application needs.

Cons:

- Higher Cost: Generally more expensive compared to other solutions like SoC or PoP.

- Special Connectors and Handling: Requires specific connectors and careful handling, which can add complexity to the design process.

- Larger Size: The integration approach of SoM typically results in a larger overall size compared to more integrated solutions like SoC or SiP.

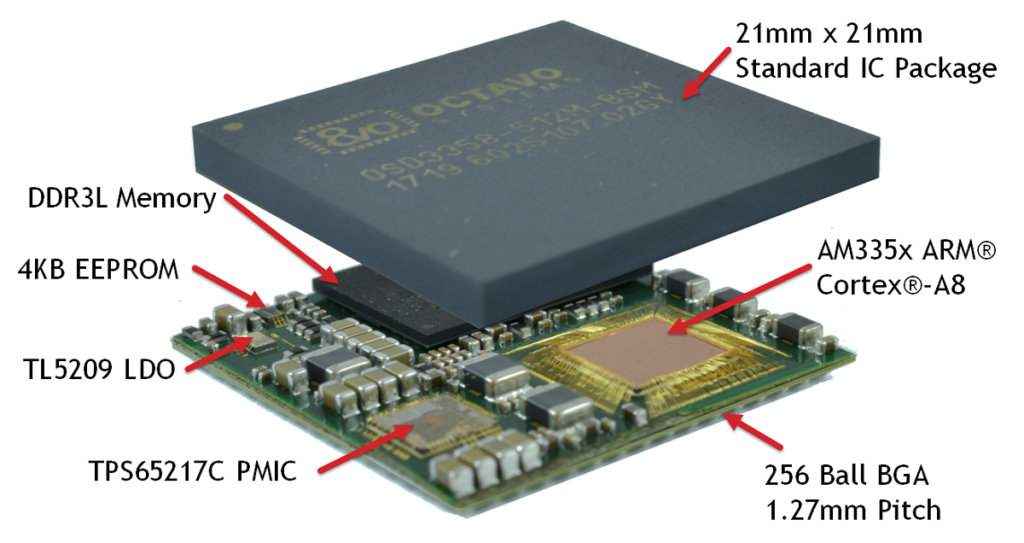

System-in-Package (SiP)

Definition and Usage: System-in-Package (SiP) technology represents a sophisticated approach to electronic system integration. Unlike traditional PCB manufacturing methods, SiP uses silicon die rather than packaged devices, leveraging integrated circuit (IC) manufacturing technologies. This allows for the integration of multiple System-on-Chip (SoC) components into a single module. By utilizing this method, SiP can incorporate various functions such as digital, analog, mixed-signal, and RF within a confined space.

The real strength of SiP lies in its ability to optimize space utilization, particularly in the Z-direction (vertical stacking), akin to the Package-on-Package (PoP) technology. This vertical integration not only saves precious board space but also facilitates enhanced performance and interconnectivity between the components.

Real-World Example: Consider advanced camera systems in modern smartphones. These systems demand high-performance image processing capabilities coupled with compact form factors. SiP technology enables this by integrating multiple image processing SoCs vertically, thereby saving space while ensuring high-speed data processing and energy efficiency.

In essence, SiP offers a comprehensive solution for complex electronic designs by combining the benefits of IC manufacturing techniques and space-efficient packaging, making it an ideal choice for high-density, high-performance applications.

Pros:

- Quick Development: SiP significantly shortens the development cycle, allowing for faster prototyping and market entry.

- Area Reduction: By integrating multiple components in a single package, SiP effectively reduces the overall footprint of the system.

- Lower Total Cost: The integration offered by SiP can lead to a reduction in the total cost of materials and manufacturing processes.

- Standard Assembly: SiP utilizes standard assembly processes, making it accessible and easy to integrate into various designs.

- No Need for Connectors: The absence of connectors in SiP designs simplifies the layout and can enhance reliability.

Cons:

- Fewer Options: SiP might offer limited options in terms of customization and component selection compared to other methods like SoM or discrete component designs.

The Ideal Choice: System-in-Package Technology

For electronic design engineers, SiP presents a compelling option. It offers a balanced combination of integration, performance, and size reduction. SiP enables engineers to bypass the complexities of very high-density board design, reduces time-to-market, and offers flexibility in integrating diverse components.

Octavo Systems, with its years of expertise in the semiconductor industry, recognizes this transition from homogeneous to heterogeneous system components. By opting for System-in-Package technology, engineers can ensure more robust, efficient, and innovative solutions for their present and future product designs.

Each of these technologies – SiP, PoP, SoC, and SoM – have distinct features and applications. Understanding their differences and strengths is crucial for electronic design engineers. With the evolution of semiconductor technology, SiP stands out as an ideal choice for those looking to create sophisticated, space-efficient, and high-performing electronic products.

Next Up

Take your electronic designs to new heights.

Join thousands of other electronic systems professionals for exclusive tips, strategies, and resources to upgrade your next design project. Expect to hear from us monthly.

"*" indicates required fields