Insights to Consider When Ramping into Production

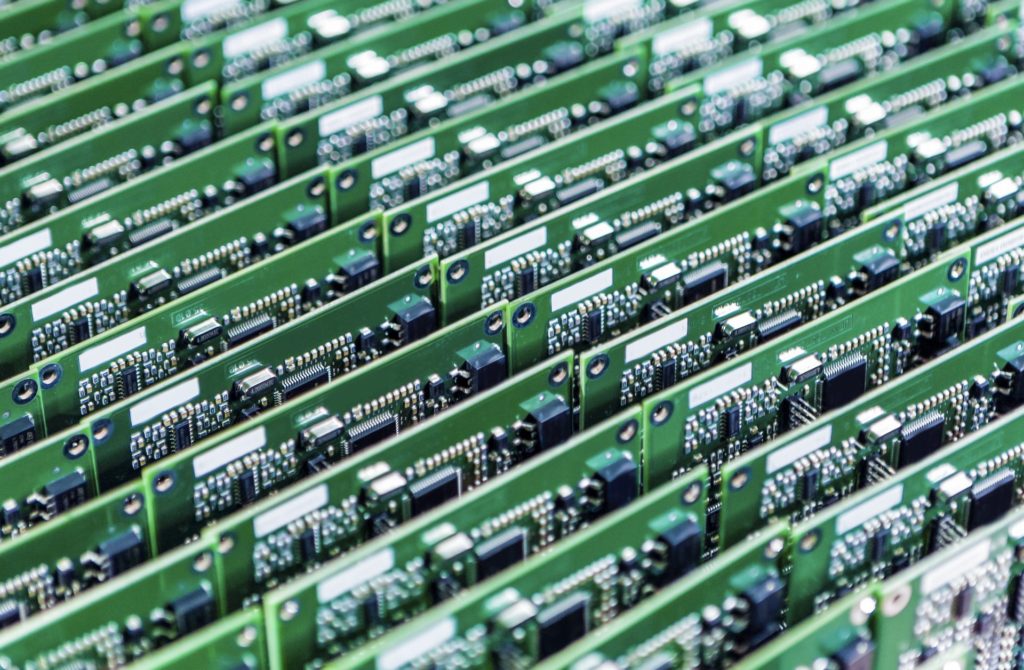

Surprisingly the hardest part of creating a new product is taking a working prototype and ramping into production. It is more complex than the architecture of the system, the hardware and software design, creating a working prototype, or taking the system through certification/qualification. The reason is simple; production requires discipline, logistics, and manufacturing at large volumes, where simple mistakes can be very expensive.

Smoothly ramping a new product into production is always the goal but seldom the reality. While it may be convenient to start thinking about production once the prototype is working, this will lead to many headaches. Successfully ramping into production starts its journey very early in the process. That means it requires paying attention to the details all the way through the process, starting with the system architecture. One thing we have learned by taking many products into production:

“Just because you can build 1 doesn’t mean you can build 10. Just because you can build 10 doesn’t mean you can build 100. And this continues with each order of magnitude.”

This paper discusses some of the insights an aids that we at Octavo have learned over the years to help you minimize the issues as you design and ramp your product into production.