Gene Frantz

Posted on August, 31, 2018

Categories

Recent Posts

- Octavo Systems Unveils the OSD32MP2 Series: Revolutionizing System Design in the Electronics Industry April 9, 2024

- Securing the Future: The Integral Role of SiP Technology in Thwarting Physical Attack Vectors in Embedded Systems March 12, 2024

- Developing Secure Embedded Systems: Best Practices and Strategies March 12, 2024

- Heterogeneous Integration (HI) and System-in-Package (SiP) Technology: A Comprehensive Overview February 20, 2024

- Understanding The Differences Between System-on-Chip (SoC), Package-on-Package (PoP), System-on-Module (SoM), and System-in-Package (SiP) January 17, 2024

SiP – Driving Heterogeneous Integration

It is always worth our while to review the state of the art of integrated circuit technology. As one who has been in the middle of it for over 40 years, it is interesting to see how we have advanced the technology by driving the learning curve, exploiting the physics of silicon and creating new ways to design billions of transistors into functioning, reliable, affordable products. The products that have revolutionized the world we live in.

I believe we are only at the beginning of a transition from integration at the component level to integration at the system level. The new heterogeneous integration method known at System-in-Package (SiP) will be the technology of choice.

That is why Octavo’s products and strategy are based on this proven technology platform known as SiP. Although the technologies associated with SiP integration have been around for over a decade and are well established in the semiconductor industry, they have not been exploited for system integration. Our goal is to develop these existing technologies, along with new concepts, to deliver to you unprecedented integration and design flexibility.

SiP technology will help increase the performance of products while increasing their reliability.

SiPs: Faster Time to Market

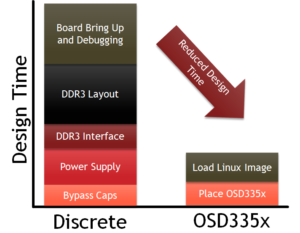

With System-in-Package, we are able to integrate ICs and passive components from different silicon processes that would be impossible to create on a single wafer. In addition to the obvious advancements of integrated circuit technology, SiP devices offer many very tangible benefits when moving to a production design.

First and foremost, SiP devices remove complex, tedious, non-value-add design tasks normally required for a PCB design by integrating them into a product that is in the package of a standard IC. While accomplishing similar or more integration than a System-on-Module, SiP devices have better signal integrity, lower power consumption, and a smaller, connector-less form factor than you get with a bulky module. By removing complex routing and power management from the system design, SiP devices also reduce the number of PCB layers required in a given design.

Another benefit of SiPs is manufacturability. Octavo products are in a standard BGA that fits well within low-cost pick-and-place and reflow manufacturing processes. SiPs can also integrate hundreds of discrete components, which reduces manufacturing time and the cost of products. In addition, the ability to integrate passive components enables single-sided designs for complex microprocessors that would otherwise need components placed directly under the device.

Finally, SiPs simplify the supply chain. Sourcing components in small quantities at a reasonable cost can be a real headache as a design moves to production. Trying to guarantee availability hundreds of components at the time of manufacture can be a daunting task. Using a SiP, sourcing is reduced to one line item in the BOM. .

Moore’s Law 2.0

You might say that integration at the system level using SiP concepts is Moore’s Law 2.0. That is, the next step in driving Dr. Moore’s original vision (not law) will be accomplished by integration at the system level. It will no longer be integration on silicon but integration with silicon. The best of the best processor, memory, analog, and power technology for a given design can be leveraged in integrated packages that take full advantage of their individual technologies.

We are on the verge of some exciting breakthroughs regarding System-in-Package. The applications will explode based on the size and capability of the integrated heterogeneous computing systems that SiP will provide.

Please contact us if you would like to keep up with what we are doing to advance the state of the art of SiP technology. It may be worth your while. We look forward to hearing from you!

You can sign up for our mailing list or follow us on Facebook, Twitter, or Linked In.