Calvin Slater

Guest Contributor

Posted on February, 8, 2019

Categories

Recent Posts

- Octavo Systems Unveils the OSD32MP2 Series: Revolutionizing System Design in the Electronics Industry April 9, 2024

- Securing the Future: The Integral Role of SiP Technology in Thwarting Physical Attack Vectors in Embedded Systems March 12, 2024

- Developing Secure Embedded Systems: Best Practices and Strategies March 12, 2024

- Heterogeneous Integration (HI) and System-in-Package (SiP) Technology: A Comprehensive Overview February 20, 2024

- Understanding The Differences Between System-on-Chip (SoC), Package-on-Package (PoP), System-on-Module (SoM), and System-in-Package (SiP) January 17, 2024

Open-Hardware Building Automation System Controller Reference Design Using AM335x Based System in Package

Some applications of IoT are still being debated. Does your refrigerator really need an operating system and be connected to the internet? Should it try to detect when you’re out of milk and automatically order more? What if there’s an error and 50 gallons shows up on your doorstep? Just like many others, I do not know the answers to all these questions. One thing I know for sure is that IoT does belong in air conditioning and the control systems of medium-to-large buildings. The OSD335x family of System-in-Package products featuring the AM335x, provides an excellent foundation for the design of an Open-Hardware Building Automation System Controller. This article introduces a series of technical application notes for building a reference design with the OSD335x-SM.

We have been installing and networking control devices in buildings for several decades now, long before IoT became a marketing buzzword. This is because the overwhelming consumption of energy in commercial buildings is due to usage from air conditioning and lighting systems. At your own house, it’s easy enough to turn off the AC and lights if you want to save some money. You can even buy one of the newer connected thermostats and lighting controllers if you want to be fancy. However, when you scale this activity to large buildings with hundreds of units, this simple task quickly becomes unmanageable without some level of automation. To conserve energy in large buildings, programmable networked controllers are used.

Why a Microprocessor System in Package Makes Sense in Building Automation System Control

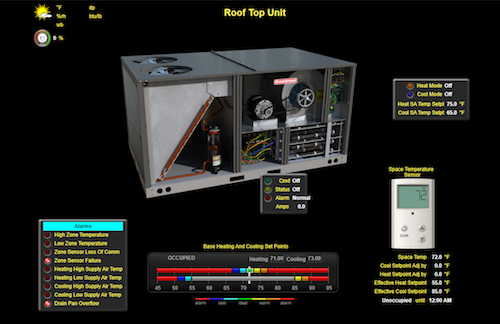

Building Automation System Controllers are flexible, multi-purpose, freely programmable embedded devices that can be found in a variety of HVAC, lighting, and security applications within a building. These devices perform a variety of tasks including monitoring and control of chiller plants, boiler plants, pumps, valves, fans, lights, indoor air quality, electric metering, occupancy detection and access control. In many cases these devices are not application specific. A controller being used on one piece of equipment can be reconfigured or reprogrammed to control something else that is completely different!

Most Building Automation System Controllers feature a quantity of 2-16 configurable remote sensor inputs that can accept a variety of industry standard signals including resistance, relay contact, pulse, 4-20mA current signaling, and 0-10VDC scaled inputs. Control of equipment can be achieved through a mixture of on-board relay outputs or analog transmitters. Applications are typically created in a visual block programming environment (similar to Node-Red). Because these devices are freely programmable (even at runtime in some cases), they often possess a good amount of processing, memory, and storage resources. The amount of computing resources needed is typically much more than a comparable application specific preprogrammed device.

Historically these devices have been constructed using microcontrollers with 1MB or less of RAM. Typical microcontrollers have on-chip RAM and Flash built into a single piece of silicon. This is the limiting factor regarding available memory of microcontroller based systems, because RAM and flash must be implemented using the same silicon process on the device. Recently due to the several factors including increased performance demands (such as cloud connectivity and web services) and lower processor costs, newer generations of building controllers are beginning to emerge that are Microprocessor SOC based.

Reduce Complexity and Cost, Increase Flexibility With A Simple Design

When examining the layout of these controllers it is observed that the Computer on Module (COM) or Core Board module (the separate board containing the SOC, PMIC, RAM and Flash) is very similar to the functionality of popular microprocessor hobbyist single board computers (SBC). The only major difference between an SBC and production controller requirements is that SBCs do not have a Baseboard that contains a power supply, connectors, transceivers, and passive devices that make the board ruggedized and suitable for industrial environments.

There are many Capes, Shields, or Hats out there that have some or many of these features, but not all of them. These system components can be integrated into a single simple, relatively inexpensive, yet ruggedized PCB Baseboard that a user could instantly have the hardware (and much of the software) to make their own Open-Hardware Building Automation System Controller design. Assuming that the board can be made for a few hundred dollars this situation would be preferable to a production controller that can cost several thousand dollars.

The Project

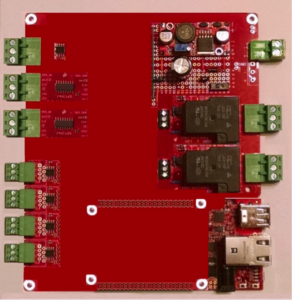

With this background in mind I wanted to design my own open-hardware building automation controller. I discovered the OSD335x-SM and decided it would be a great platform for my controller. It integrates many of the components that would normally be on the COM board into a single IC device.

My initial plan was to utilize the Octavo Systems OSD3358-SM-RED Reference, Evaluation, and Development Board as the main processing module and build an expansion card specific for building automation control.

However, as I started digging into the details of the OSD335x-SM I realized that the SiP integrated almost all the components that would typically be on a separate COM board into a single device. This meant instead of a two board solution I could design a single board that incorporated the computing components and the interfaces. This will significantly reduce the cost of the end system.

Over the next few weeks I am going to walk you through the design of an open-hardware building automation controller with the specs outlined in the box below. You can also get access to all my design files through my GitHub.

Single Board Open-Hardware Building Automation Controller Specs

2) (1) Fully isolated RS-485 transceiver port module each with (3) position pluggable right-angle industrial type screw connectors supporting up to 115k BAUD rate communications. Isolation with reference ground is critical for reliable communication across networks spanning long distances (up to 4000ft).

3) (1) CAN Bus transceiver port module for addition of high speed I/O expander board(s). Connector shall be a (3) position pluggable right-angle industrial type screw connector.

4) (6) Analog Universal Input modules (UI-Basically a voltage divider and/or pull-up circuit with simple low-pass RC filtering), supporting Thermistor/Dry Contact, Pulse, 4-20mA, and 0-10VDC, industry standard input signals (jumper selectable).

5) (5) 10A Form A relay Binary Outputs (BO) each with pluggable right-angle industrial style screw connectors.

6) (1) Fused 24VAC half-wave-rectified power supply with (2) position pluggable right-angle industrial type screw connector. Half-wave power is important to avoid grounding issues with other low voltage building automation devices on the same circuit.

7) Dual rotary decimal number selector switches and (1) four position dip switch connected to HC165 shift registers. These are used for serial load of user defined device configuration settings at startup.

8) Board edge connector varistor-type or similar Surge Protective Devices and passive EMI filtering where applicable.

9) Supercap and/or Battery Backup module for Hibernation/RTC support in the event of power loss.

About our Guest Author:

This article was guest written by Calvin Slater who is a senior controls engineer that has spent eight years in the Building Automation System Control Industry and is highly interested in embedded hardware as well as open-source building automation frameworks. He is also a contributing editor for AutomatedBuildings.com where he has authored a series of articles on the system edge controller.