Gene Frantz

Posted on February, 28, 2017

Categories

Recent Posts

- Octavo Systems Unveils the OSD32MP2 Series: Revolutionizing System Design in the Electronics Industry April 9, 2024

- Securing the Future: The Integral Role of SiP Technology in Thwarting Physical Attack Vectors in Embedded Systems March 12, 2024

- Developing Secure Embedded Systems: Best Practices and Strategies March 12, 2024

- Heterogeneous Integration (HI) and System-in-Package (SiP) Technology: A Comprehensive Overview February 20, 2024

- Understanding The Differences Between System-on-Chip (SoC), Package-on-Package (PoP), System-on-Module (SoM), and System-in-Package (SiP) January 17, 2024

Why System in Package Technology Must Replace System on a Chip Technology

System on a chip (SoC) technology has got us a long way, allowing for entire electronic systems to be integrated into a single microchip, and SoC technology has long been the driving force behind smaller and smaller electronic systems with higher and higher levels of performance. Like all great technologies, though, SoC technology must eventually give way to something even more innovative and effective. In an article published by Stephan Ohr on EE Times, Ohr discusses how the increasing costs of transistor scaling has made SoC technology less viable and has created a demand for a specialized design process, and we at Octavo Systems completely agree with that assessment. With current manufacturing trends demanding an efficient process to manufacture an entire electronic system at one time and at increasingly smaller sizes, SoC technology is no longer an optimal solution. Fortunately, we have a replacement–System in Package (SiP) technology.

What is System in Package Technology?

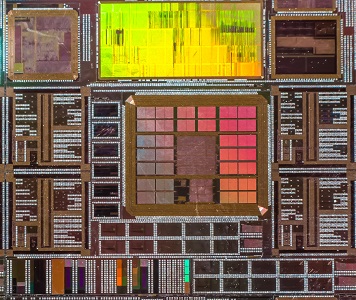

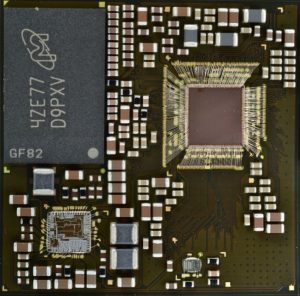

System in Package (SiP) technology is simply combining a number of integrated circuits together in one highly compact module (package) and that function as one unit. In SiP, integrated circuits are attached to a substrate then electrically connected via fine wires within the package. Rather than focusing on how many transistors we can fit onto one piece of silicon, SiP technology aims to develop new and innovative ways to integrate system components into a single package. This is especially valuable in space-constrained designs, and SiP technology has paved the way for smaller and smaller electronic devices by decreasing the complexity of circuit boards and eliminating the need to add a large number of external components in order to make the device function. In this way, SiP technology has been the driving force behind miniaturizing devices that once would have been too complex for SoC methodology to make work.

Why SiP is Replacing SoC

System in Package (SiP) technology was born out of the overwhelming success of Moore’s Law. Moore’s Law has allowed for the production of semiconductors that are less expensive, dissipate less power, and have higher performance. What it has also done, however, is make it so there is no longer one semiconductor manufacturing process that works for all of the components which

make up a system. For SoC to work at a system level, one or more necessary components will need to be severely compromised. As more devices begin to rely on integrating components into a single system, SoC is losing its viability as a cost efficient, functional option for system integration. SiP, however, opens the door for the design of a near limitless variety of complex systems. While SiP is already a popular methodology in a variety of industries, our goal at Octavo Systems is to promote SiP as the go-to technology for all facets of electronic design.

Opportunities SiP Provides

One of the biggest opportunities SiP provides is for the production of specialized sensors that will be affordable enough to have potential on the market. One example of such sensors would be smart sensors placed inside of cups at coffee shops. Many coffee shops already provide free internet, encouraging visitors to linger and hopefully order more coffee. However, for a customer to order more coffee they must get up from their seat, leaving their computer behind and risking losing their seat to go stand in line. In this way, ordering more coffee becomes inconvenient for the customers and hurts the coffee shop’s chances of making a sale.

With a smart cup, however, sensors could be integrated into the cup, alerting the barista when the coffee in the cup is almost gone or has grown cold so they can come by with a fresh cup of coffee. The cup then becomes a sort of an “infinity cup” that is continually replenished, and the customer’s credit card charged, without the customer ever having to leave their seat. If the cup is sold to the customer as a personal cup, the barista could be alerted as soon as the customer walks through the door with the cup and could begin making the customer’s order. Alternatively, the customer could choose to have a menu of drinks for the day, in which case the barista would wait for the customer to place their order as normal.

As the Internet of Things becomes increasingly more of a reality rather than just a concept, the need for a multitude of affordable, highly functional sensors grows more apparent. The SiP methodologies we are pushing for at Octavo Systems help make those sensors possible.

Another great example of the innovations SiP provides can be found in imaging systems. SiP technology allows for devices as complex as a high-resolution camera to be produced at incredibly small sizes. Several years ago I was involved with a medical research team at USC as they were creating artificial vision. The aspect of their research that encouraged me was their designing a camera that could be surgically implanted into the eye of the patient, and the end goal of the project was to produce a camera the size of a grain of rice. Before SiP technology, a camera of this size would not have been possible. However, using the advantages of a SiP solution, the team at USC was able to conceive a viable design that could provide artificial sight to a blind patient.

These two examples are just a small sample of the opportunities involved with embracing SiP technology. We at Octavo Systems believe that SiP technology is soon to become the new poster-child for technological innovation, paving the way for an unimaginable number of new and innovative designs.