Gene Frantz

Posted on March, 4, 2016

Categories

Recent Posts

- Octavo Systems Unveils the OSD32MP2 Series: Revolutionizing System Design in the Electronics Industry April 9, 2024

- Securing the Future: The Integral Role of SiP Technology in Thwarting Physical Attack Vectors in Embedded Systems March 12, 2024

- Developing Secure Embedded Systems: Best Practices and Strategies March 12, 2024

- Heterogeneous Integration (HI) and System-in-Package (SiP) Technology: A Comprehensive Overview February 20, 2024

- Understanding The Differences Between System-on-Chip (SoC), Package-on-Package (PoP), System-on-Module (SoM), and System-in-Package (SiP) January 17, 2024

System in Package: the Complement to Moore’s Law

Moore’s Law has served us well for over a half of a century. It drove the semiconductor (SC) process technology roadmap. It got us to think about putting more transistors on an integrated circuit to the point where it is no longer a nightmare to consider billions of transistors on one piece of silicon. In fact, several years ago I began to use the phrase “transistors are becoming a buck a billion” to put a new perspective on the success of Moore’s Law.

But even with the great success the SC industry has had, we continue to find ourselves unable to accomplish the ultimate goal, a complete system on a chip. Yes, we talk about System on Chip (SoC) technology as the solution (now what was the problem again?). However, the advancements in IC technology have actually defeated the primary goal of SoC, the integration of a complete system on a single piece of silicon. In the past I have actually suggested that it should be SSoC rather than SoC as all we have been able to do is a Sub-System on a Chip.

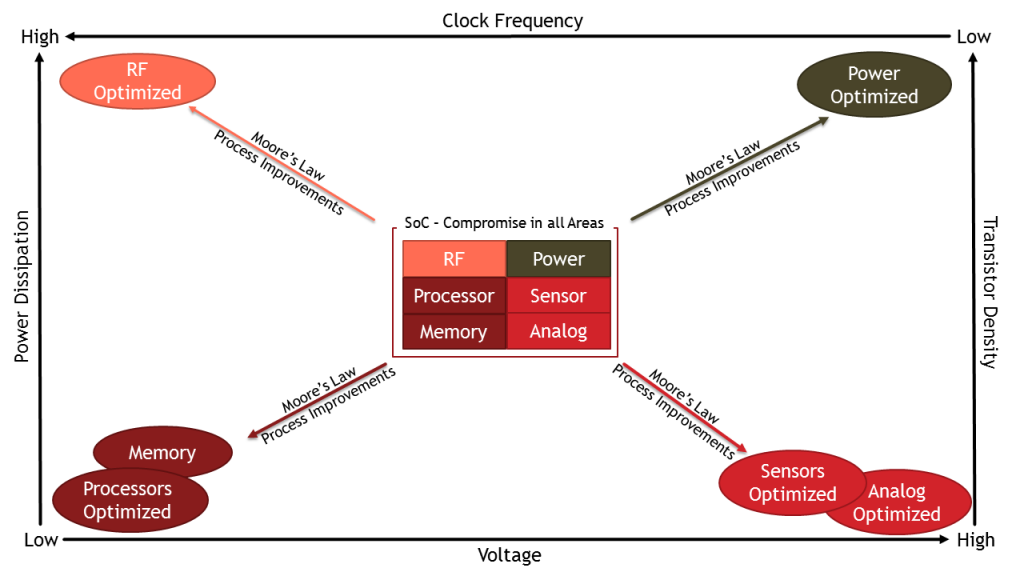

So why can’t we put a complete system on one device? Why haven’t we, through all of the advances, been able to truly get the entire system on a single piece of silicon? Let’s take a step back and look at the type of components that go into a system. They include processors, memories, analog, power management, RF communications, sensors, energy scavengers, and many more. Each of which use a different SC process that has evolved in part by chasing Moore’s Law to optimize its peak performance. We no longer have just one IC manufacturing process. We have created processes to be optimized for specific needs. There is a specific process for high performance microprocessors, another process for memories, another for high performance audio, another for power management, another for RF circuits . . . have you caught the drift?

You can argue that an optimal SC process should be able to include all of the different types of components. However, the laws of physics as we know them today don’t allow this to happen. We can mix different types of components onto a single process but significant compromises will have to be made. The only way to achieve the optimal performance out of a system is to have each component use its own optimized process. So you end up with a design where all of the digital circuits are integrated into a digital SoC , the analog circuits into an analog SoC, the power circuits into a power SoC, and so forth. (See figure to the right)

That leads me to a complementary capability introduced to the industry about a decade or so ago. This new ability enabled different components from different SC processes to be integrated into a single package that can be used by system designers. There are several ways to accomplish this and they have different names, such as Multi-Chip-Module (MCM), System on Module (SoM), or System in Package (SiP). From our perspective, the concept of a System in Package (SiP) best describes the ultimate concept. The reason for our use of SiP is simple:

- A System consists of many components including analog, digital, and power ICs, as well as other active circuits like transistors, diodes, MeMs and sensors. You also need to include passive devices like resistors, capacitors and inductors.

- In-Package means all of the components that make up the system are in a Single Package that looks like an IC.

So to the outside world a SiP looks like a complete electronic system in single package.

However, as a system designer, even with SiP technology bringing to together different SoC processes along with other electronic components a true complete System-In-Package is still hard to achieve. I’ll give you a hint why I am saying this – the SiPs today still have pins on the package. The ultimate electronic system should not need pins, right? But I’ll save that discussion to a later post. Let me get back to the topic.

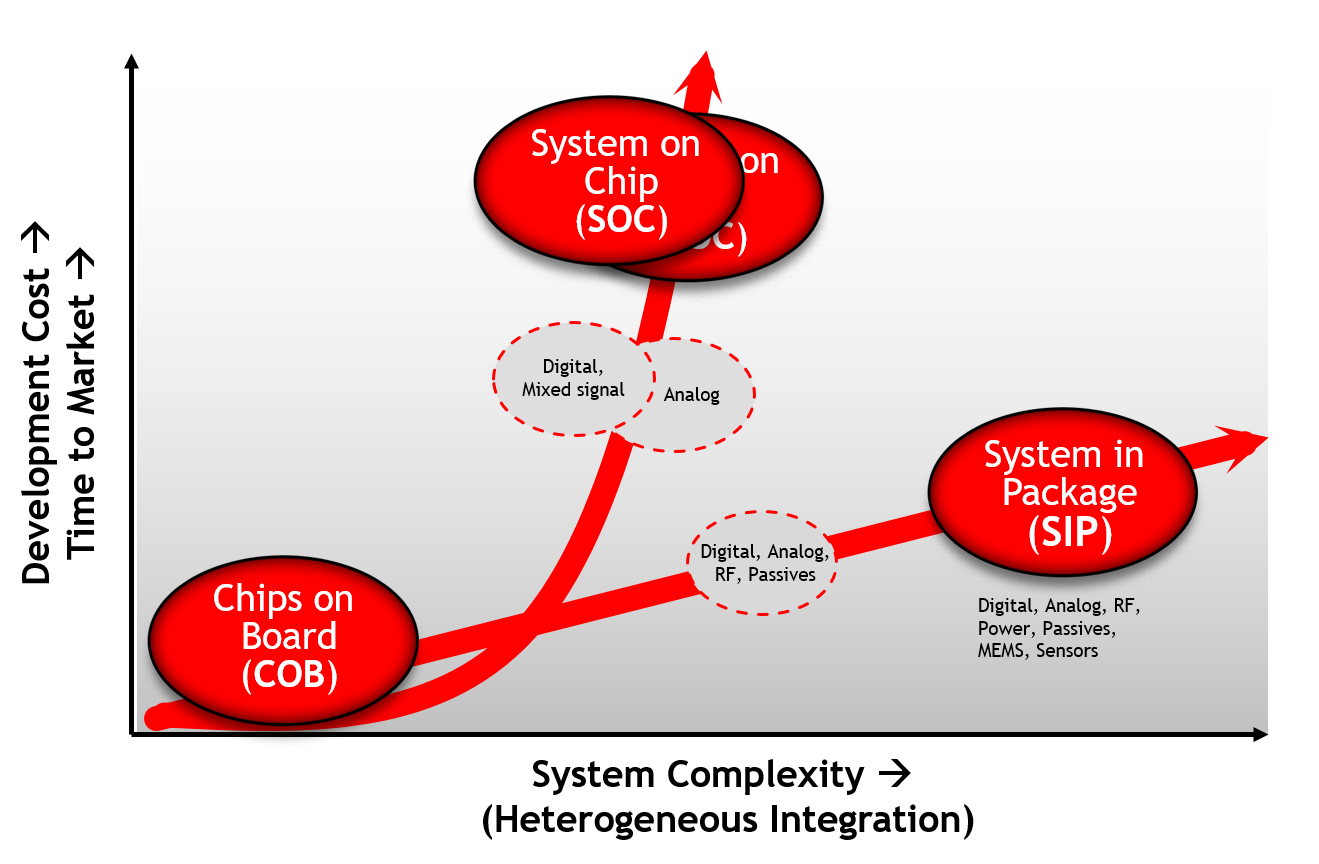

What brought us to needing SiP technology can be best seen by going back to the origin of the integrated circuit and following its evolution. But just as with the earlier “not needing pins” comment, we will discuss this evolution in more detail in a later blog. For now I will simply say that as we optimized the manufacturing processes for the different kinds of circuits, the ability to put those different kinds of circuits onto the same SoC became difficult, if not impossible. The only way to continue to integrate these different SoCs is through the use of a SiP. The following figure attempts to describe that issue.

Now that we went through why SiPs are needed, if you want more information on how Octavo Systems is bringing this technology to the masses check out our series on SiP technology and the Challenges here.